Industrial Labels

Industrial labels adapt to any requirements and environments.

Seamlessly recorded from production to disposal: “Hybrid” labels collect, store and process all of a product's information throughout its lifecycle.

Digital data-driven processes, fully networked production and fully automated manufacturing are the most important components of Industry 4.0 and have the potential to optimize processes and reduce costs. One of the important prerequisites for this is components, assemblies and containers equipped with RFID labels.

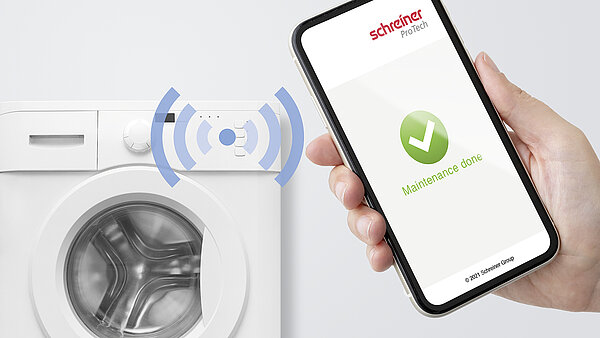

RFID technology gives each part its own identity, enables independent control in the production process and seamless recording across the entire supply chain. RFID and NFC labels from the Schreiner ProTech division enable a seamless traceability process.

In many industrial applications, the strong influence of metal on the electromagnetic field makes the reliable use of RFID technology difficult. By using shielding materials, the functionality of our RFID labels is also ensured on metallic surfaces.

Conventional RFID-Labels lead to poor reading results on ESD containers and ESD production carriers. Our labels are specially adapted to this application.

The RFID windshield label enables automatic, automatic vehicle identification (AVI) in a wide range of applications.

The secure labeling of reusable containers or logistics racks, including the management of number ranges, is a challenge that we master.

The label allows the identification of products by means of HF RFID. Once applied, the label cannot be removed without destroying it—thus ruling out reuse or unauthorized use.

NFC (Near Field Communication) is a transmission standard based on RFID technology for the contactless exchange of data via radio technology over short distances of a few centimeters, thereby allowing interactive labeling.

In every decision cycle for the deployment of an RFID solution, the technical feasibility must be tested in real processes on site. The RFID feasibility study serves to prove the function of the notified solution on-site at the customer's premises.

Efficient labeling processes depend on fast, high-quality printing and optimum label application. The Zebra R110Xi4 desktop printer can easily print and program UHF DistaFerr labels.

Readers and antennas are used to read RFID labels. All ranges from a few millimeters to several meters are covered. In this way, applications ranging from workpiece carrier ID to reading portals can be realized.